© 2025 IceStoneUSA. All rights reserved.

Made with ❤ in the USA

Each IceStone slab is made by hand and is a representation of true craftsmanship, design, and sustainable manufacturing. IceStone’s glass is thoroughly researched and tested to ensure it is up to our high level of standards. Each slab is uniquely made with extreme attention to detail and handled with care.

Step 1: Batching

The batching process is where we mix the glass,cement, and non toxic pigment. The mixture then pours out into a tray creating a mold and placed on a vibration table to distribute the glass throughout the slab.

Step 2: Curing

After batching, the IceStone slabs are entered into a steam powered kiln to cure overnight. Curing is done to rid the slab of any moisture and humidity.

Step 3: Calibration

Calibration is where we shave off a thin layer of the bottom of the slab to ensure that it is even and the thickness is consistent.

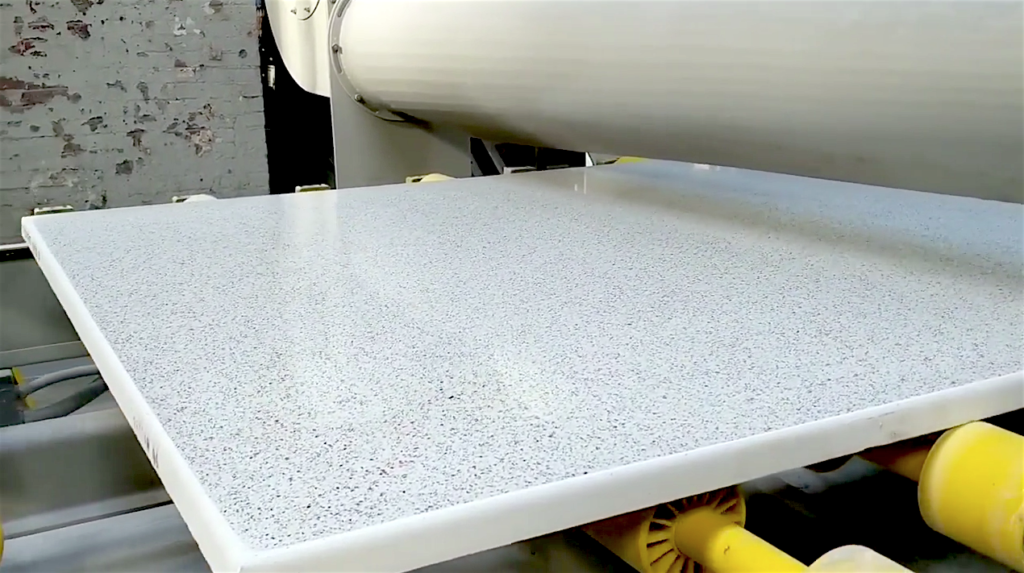

Step 4: Polishing

The IceStone slab is placed in the polishing machine to give it a shiny, glossy look.

Step 5: Patching & Sealing

Once polished, we patch up any imperfections and seal the surface.

Step 6: Ready to Ship!

The slabs are placed into inventory and ready to ship.

IceStone surfaces are more than products, they are a manifestation of our ideals. We are a triple bottom line company. We measure our success by more than profits.

We also ensure that our employees are empowered and we are doing everything we can to be good stewards of the planet and that we continually invest in the health and dignity of all of our people. Our values inform everything we do. So when you invite an IceStone countertop into your home or business, you can feel good about how it got there.

IceStone began in 2003 with a simple concept; transform waste glass into something beautiful. The founders set out to create a business that integrated sustainable, responsible practices from process to product, and to provide a high design solution that would address a real need. With capital investment from over 70 progressive angel investors including Ben Cohen from Ben & Jerry’s, activist and author Dal LaMagna, the founder of Tweezerman, Greg Steltenpohl from Odwalla, and Gary Hirshberg from Stonyfield Farm, IceStone recycled glass surfaces were brought to market.

Since then, IceStone has diverted over 20 million pounds of glass from landfills. IceStone’s signature recycled glass and cement products remain an icon of the new countertop industry, delivering unparalleled style that brings design projects to life.

IceStone has been at the forefront of the B-Corporation movement that seeks to change the way companies define success.

Certified B-Corporations are businesses that meet the highest standards of verified social and environmental performance, public transparency, and legal accountability to balance profit and purpose. B-Corps are accelerating a global culture shift to build a more inclusive and sustainable economy.

Today there are more than 2,600 Certified B-Corporations across more than 150 industries and 50 countries, unified by one common goal: to redefine success in business.

IceStone’s factory is a testament to our commitment to conservation and reuse. Our 100% recycled glass and toxin-free manufacturing is just part of the story.

Our facility is daylit with skylights, uses a water recycling system, and steam powered kilns. Any unusable glass or cement can be recycled. Our goal is to become a zero-waste plant. We are pretty close; we currently recycle over 90% of our waste!

IceStone’s commitment to second chances goes beyond our factory and our products. We hire the homeless, refugees and train the formerly incarcerated and ensure that everyone gets paid a living wage and has access to subsidized health insurance and a voice in the company.

© 2025 IceStoneUSA. All rights reserved.

Made with ❤ in the USA

This website uses cookies to improve your browsing experience, analyze website traffic and provide personalized content. By using this website, you consent to the use of cookies in accordance with our privacy policy.